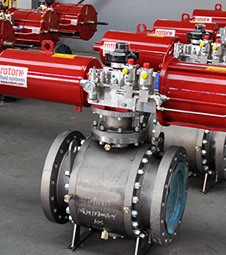

API 6D Expanding Gate Valves

The RANGER expanding gate valves are made to serve petroleum, gas, chemical, water, and slurry applications with an emphasis on reliability, safety, and positive shut-off.

Key Application(s)

- Pipeline/Transmission lines

- Tank farms

- Custody transfer

- Any application that reliable positive shut-off is required

Design Features

- Sizes from NPS 2” to 30”(DN50 to DN750)

- CLASS 150 to 2500 (PN20 to PN420)

- Operating temperature -196℃ to 593℃(the range of service temperature may vary for different materials)

- The sealing faces of the valve seat and valve face are hard-faced to improve the erosion resistance and extend the service life of the valve

- SS+graphite (spiral-wound) or metallic seal (RTJ) or pressure seal bonnet is used to provide a reliable bonnet seal

- Rising stem position for visual indication of disc position

- The valve stem thread is isolated from the pipeline media to reduce corrosion

- The expanding gate design reacts to thermal cycling while maintaining a seal.

- High CV due to full port design

- Optional Class A sealing testing available to meet the fugitive emission standard ISO 15848 FE

Reference

Design Standard(s)

- API 6D

- ASME B16.34

- GB/T 12234

- GB/T 12224

Face-to-Face

- ASME B16.10

- GB/T 12221

End Connection

- ASME B16.5

- ASME B16.47

- ASME B16.25

- GB/T 9113

- GB/T 12224

Test Standard(s)

- API 6D

- ISO 5208

- GB/T 26480

- GB/T 13927